Materials & Technology

Powder Coating Process for Water Bottles Explained

Introduction: Why the Powder Coating Process Matters for Water Bottles

For wholesalers, OEM drinkware brands, and corporate gift buyers, the powder coating process is one of the most important factors determining a water bottle’s durability, visual appeal, and long-term quality.

As a professional custom water bottle manufacturer, we use powder coating on stainless steel and aluminum bottles to achieve premium finishes, scratch resistance, and long-lasting color performance. This article provides a detailed, SEO-optimized explanation of the powder coating process and what buyers should look for when choosing a manufacturer.

What Is Powder Coating?

Powder coating is a dry finishing process that uses electrostatically charged powder to create a strong, protective, and decorative layer on metal surfaces.

Why Powder Coating Is Used in Water Bottle Manufacturing

-

It creates a harder, more durable finish than liquid paint

-

Zero VOCs, meeting global environmental regulations

-

Ideal for stainless steel and aluminum drinkware

-

Supports custom Pantone colors and special textures

-

Cost-effective for large volume production

This is why top outdoor drinkware brands rely on powder coating as their signature finishing method.

Benefits of Powder Coated Water Bottles

1) High Durability & Impact Resistance

Powder coated water bottles are resistant to:

-

Scratches

-

Chips

-

Minor impacts

-

Daily wear

The coating forms a tough shell that enhances longevity.

2) Excellent Color Retention

The powder coating process provides UV stability and prevents colors from fading—important for outdoor and sports bottles.

3) Eco-Friendly Manufacturing

Because powder coating contains no solvents, it meets the requirements of eco-conscious brands and EU environmental standards.

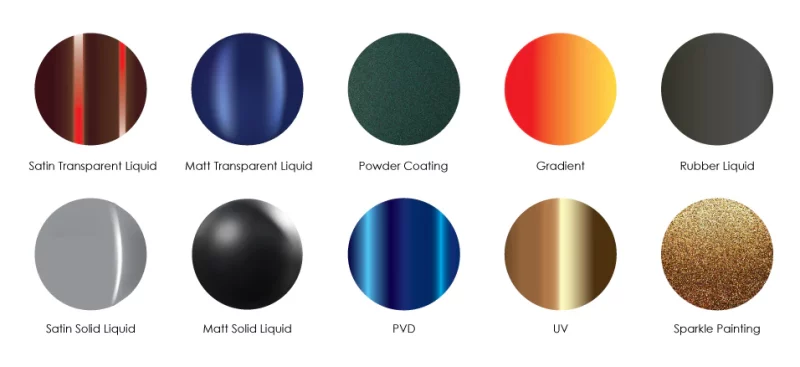

4) Wide Range of Custom Finishes

OEM brands can choose:

-

Matte

-

Glossy

-

Textured

-

Gradient

-

Soft touch

-

Metallic effects

This makes powder coating ideal for custom private-label drinkware.

Common Types of Powder Coating for Water Bottles

1) Polyester Powder Coating

Best UV resistance; commonly used for outdoor bottles.

2) Epoxy-Polyester Hybrid Powder Coating

Smooth and cost-effective; ideal for indoor gift products.

3) Textured Powder Coating

Anti-slip and highly durable; ideal for sport water bottles.

4) Soft-Touch Matte Coating

Creates a beautiful velvet-like finish, popular for minimal brands.

Different resins affect the final performance, and factories choose based on the intended market and usage scenarios.

Step-by-Step Powder Coating Process for Water Bottles

Step 1: Bottle Surface Inspection

Every stainless steel or aluminum bottle is inspected for:

-

Welding quality

-

Surface dents

-

Deformation

-

Manufacturing defects

Only qualified bottles move to pretreatment.

Step 2: Pretreatment

Pretreatment ensures strong powder adhesion.

Processes include:

-

Sandblasting

-

Degreasing

-

Rust removal

-

Surface activation

This step is crucial for ensuring the powder coating layer is smooth and durable.

Step 3: Degreasing and Water Rinsing

Multiple rinsing tanks remove oils and residues.

If the bottle is not cleaned properly, pinholes and uneven color will occur.

Step 4: Drying

Bottles enter a drying oven to remove all moisture.

Even small droplets can cause defects in the coating.

Step 5: Electrostatic Powder Application

This is the core of the powder coating process.

How it works:

-

Powder is charged with a negative electrical charge

-

Bottles are grounded

-

Powder is attracted evenly to the surface

High-end factories use automated robotic sprayers to ensure consistent thickness.

Step 6: Curing in the Oven

Typical curing range:

-

170–200°C

-

10–20 minutes

During curing:

-

Powder melts

-

Resin cross-links

-

A durable protective shell forms

Proper curing ensures excellent adhesion and scratch resistance.

Step 7: Cooling & Quality Control

After curing, bottles cool naturally.

QC includes:

-

Adhesion testing

-

Cross-hatch testing

-

Hardness testing

-

Color consistency check

-

Visual inspection

Only bottles that pass all QC tests move to the printing stage.

Quality Standards for Powder Coated Water Bottles

1) Adhesion Test

Checks whether the coating bonds properly to the metal.

2) Pencil Hardness Test

Measures surface hardness and scratch resistance.

3) Cross-Hatch Test

Ensures the coating will not peel under daily use.

4) Salt Spray Test

Evaluates corrosion resistance for outdoor bottles.

These tests help OEM buyers verify whether a factory can produce high-quality powder-coated bottles consistently.

Common Powder Coating Defects & Prevention

1) Orange Peel

Causes: Low curing temperature, excessive thickness

Solution: Optimize powder flow rate and oven temperature

2) Pinholes

Causes: Moisture or oil contamination

Solution: Improve cleaning and drying process

3) Uneven Color

Causes: Inconsistent spray path

Solution: Use automated spray robots

4) Peeling or Flaking

Causes: Poor pretreatment

Solution: Strengthen surface preparation

A reliable manufacturer has SOPs to control each defect.

OEM Customization Options for Powder Coated Water Bottles

We offer full customization, including:

-

Custom Pantone colors

-

Multi-tone gradients

-

Matte / Glossy finish

-

Stone-texture coatings

-

Rubberized coating

-

Soft-touch matte

-

Textured anti-slip coating

-

Laser engraving, UV printing, or silk screen logos

Perfect for private-label brands, corporate gifting, and wholesale distribution.

How to Choose a Reliable Powder Coating Factory

When sourcing OEM water bottles, look for:

✔ A clean powder coating workshop

Dust causes coating defects.

✔ Automated powder coating equipment

Ensures consistency for large orders.

✔ Complete quality control system

Ask for adhesion, hardness, and salt spray test reports.

✔ Stable material supply

Covers stainless steel, aluminum, lids, and accessories.

✔ Proven OEM experience

Manufacturers familiar with branding requirements can produce better results.

Conclusion

Understanding the powder coating process helps buyers evaluate quality and choose the right drinkware manufacturer. A well-controlled powder coating line ensures:

-

Strong adhesion

-

Premium texture

-

Uniform color

-

Durable finish

Whether you are a wholesale distributor, OEM drinkware brand, or corporate gift buyer, choosing the right factory ensures product consistency and market competitiveness.

If you need custom powder coated stainless steel or aluminum bottles, we can support full OEM/ODM production.

SEO Keyword-Optimized FAQ Section

1. Is powder coating safe for stainless steel and aluminum water bottles?

Yes, powder coating is safe and used by leading drinkware brands worldwide.

2. How durable is powder coating?

With proper curing, powder coating can last 3–5+ years without peeling or fading.

3. Can I request custom Pantone colors?

Yes, we offer Pantone color matching for all OEM water bottle orders.

4. What surface finish options are available?

Matte, glossy, soft-touch, textured, and gradient finishes are all available.

5. What is the MOQ for custom powder coated bottles?

Typically 200–500 pcs per color, depending on the style.